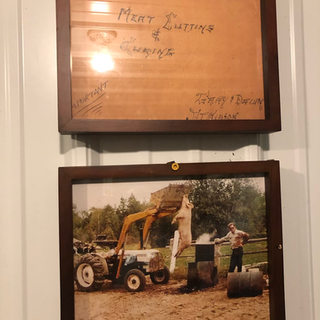

Last year we had an appointment with a local butcher to process a beef for us. Appointments are hard to come by and usually are booked 6-8 months ahead of time. About 2 weeks before the appointment the butcher called and said that he was cancelling and closing his business. This was a huge problem. We were going through hay fast and needed to downsize in order to stretch the supply throughout the whole winter months. We had wanted to build a meat cutting room and this only triggered the process into an active project, but that meant another clock to beat. Kenny worked hard at taking an existing cement pad that we had and built a room over that footprint. My mom and dad had given us their meat cutting equipment and we gathered other salvaged materials to make a room that would at least be an organized designated place with equipment and counter space.

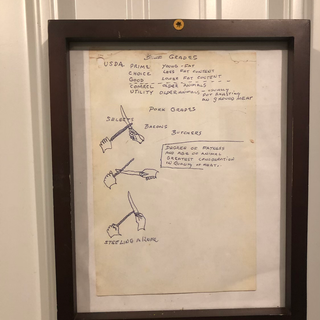

This project also spurned a walk down memory lane. Kenny had always cut the meat with my dad and dad had taught him about cutting all the different cuts of meat. Mom and I were the ones on the other end, our job was to do the packaging. When we had the room ready and were ready to do our beef, Kenny had said that he wished he had dad's folder that he used every time they would cut meat. I had no idea what he was talking about, but asked mom if she knew. She knew exactly where it was and was happy to give it to Kenny for his "toolbox" for reference. This folder was so neat to look through, it contained hand drawings and diagrams of meat cuts that my dad had made. It also included recipes for preserving meats and foods. I decided to copy every page and make individual binders, One for a person in each family of my siblings for a keepsake. I tried to gear the binder recipient by who would be more likely to use it and glean from the hidden knowledge of a time left behind. I also copied all of the diagrams and framed them for the walls of the cutting room. I figured this would give a touch of dad and also be very handy when it came time to cut for a quick reference.

Along with a place to prepare and cut we would need a cooler that would ensure the meat would be cured at the right curing temperature. Usually you would butcher at the time of the year that the temperatures are cooler and curing temperatures, but there are times you need insurance. These walk-in units cost thousands of dollars to build and that was not really in our budget, so a researching I would go! We had thought about using an air conditioner in a really insulated room, but soon found out that wouldn't work. The problem was that air conditioners are programmed so that they won't go “cool enough” to be a good curing temperature. I found a really neat product called a "cool-bot . It is an easily installed add-on that tricks the air conditioner to run at a lower temperature, making it the proper curing temperatures.

It was an easy install and saved quite a bit, considering what a walk-in cooler would cost to buy. It also has had no glitches or anything that would make us feel skeptical as to if it is going to stay working properly. They are a small company that is very much into helping and service. Just for giving feedback they doubled the warranty and stand by their product with personal contact to help with problems. They are very dedicated in helping the individual become more independent with having their own cooler and are interested in how to make their products better.

I decided to do a referral and get a link to help anyone who may want to do the same without having to do the research and recommend the cool bot. They gave us a referral link to use which would give someone $20 off the price! :https://storeitcold.referralrock.com/l/LBXP341F/

Comments